The ABCs of ERP

An Introduction to ERP Solutions for Building Material Distributors

Expansion, like most everything else in business, is a balancing act.

Unless properly controlled, it will harm your business more than help it, as unforeseen or unplanned growth can spiral overhead, costing time, money, existing business, or even your reputation. Alternatively, simply maintaining the status quo to limit the expenditure of resources is usually a shortcut to obsolescence. Figuring out how to grow profits, and not just headcount, requires experience, guts, and an eye for detail.

So the question faced by anyboy who would grow his business becomes: how do I increase my output without consuming a directly corresponding amount of capital, man-hours, or other resources? The answer is to scale your operations by implementing an ERP solution.

Definition of ERP

ERP, or Enterprise Resource Planning, is the description given to software applications that integrate core business functions, like estimating, order management, accounting, and logistical management, into a single system to simultaneously increase capacity and cost savings. For the construction product industry, specifically Division 8 and Division 10 manufacturers and distributors, ERP solutions should also include functionality that supports contract sales, change order management, shop orders, special materials ordering, contract billing, route and delivery scheduling, service, and installation.

At their most basic, ERP solutions scale productivity by supporting, or completely replacing, manual systems and processes with automated systems and processes. For example, a single, integrated estimating, ordering, and invoicing platform can allow project managers to access accurate and up to the minute information about the health and financial situation of their projects – information that would otherwise be too difficult or time consuming to uncover. Such visibility can have a huge impact on decision-making, customer success, and the overall financial viability of the company.

Evolution of ERP

To understand what a modern ERP solution is, and why so many of them are so different, it’s important to know where ERP solutions first came from. While the term ‘ERP’ was coined in the 1990’s, the root of the solution can be traced back to accounting systems from the 1960s. These relatively simple programs expanded to include reconciliation functions and status reports for inventory control, a family of functionality that came to be known as MRP (Material Requirements Planning).

As demand for the kind of reliability and efficiency offered by automated accounting spread to other areas of the organization, MRP solution publishers added functionality to manage production processes and scheduling, and coined the enhanced system ‘Manufacturing Resource Planning’, or MRP-II. With the integration of customer relationship management, analytics, and advanced planning, MRP-II transitioned into what we would recognize tpoday as ERP software.

Objective of ERP

The obvious productivity gains promised by integrated business operations clearly show the potential of an ERP solution. However, the real value of ERP lies in its ability to recast the traditional relationship between risk and reward.

We’ve all heard the golden rule: in order to win big, you’ve got to take big risks. This certainly holds true in many business cases, however when

implemented intelligently, the right ERP solution can transform that relationship, making it possible to achieve greater stability and profitability through minimized work and exposure – a phenomenon we call Work Small/Win Big. But, in order to capitalize on the expanded promise of ERP, owners must carefully consider various ERP options, and implement only a solution capable of meeting the challenges unique to their busi

Components of ERP

The standard features that an ERP solution should include – its definition, if you will – varies considerably depending on the software publisher or expert that’s providing it. Even general terms describing the component functional areas of a solution can have fairly divergent practical applications from industry to industry. Job Costing, for instance, looks different to general contractors than it does to made-to-order manufacturers; but since job costing is a standard requirement for most ERP deployments, it would be easy to assume it means the same thing to everybody. To ensure that you get what you actually need, it

is important to carefully review and understand how common descriptions apply within a specific ERP solution.

Today there is a broad spectrum of ERP options available on the market. Picking the right one involves careful business analysis, preparation and research; and for the door and hardware industry there are additional special considerations. Whether your company is looking for a simple accounting program like QuickBooks or a comprehensive platform, doing the legwork up front, or working with a trusted consultant who knows the ins and outs of the ERP world, will go a long way in your overall satisfaction (and profitability) down the road.

ERP for Door and Window Suppliers

Division 8 supply businesses are challenging to effectively operate. Often, managers depend on old school, people-based workflows and homegrown processes to track and manage a staggering amount of detail – all on relatively thin operating margins. Additionally, the estimating, ordering, fulfillment, and billing practices of the door and window supply industry are uniquely ‘contract-based’, rendering ERP solutions that work for most other industries inadequate.

For a Division 8 supplier to truly benefit from an ERP solution, it must do two things in addition to the ‘standard’ functionality found in generic ERP offerings: convert tribal knowledge into business assets, and support existing workflows.

Supporting Existing Worflows

No matter how efficient an ERP solution may be, it has no value in an organization that cannot adopt it. There is often a discrepancy between industry- specific practices and how software is designed to manage or account for them, leading to the need for customization, manual workarounds, or supplementary technology. In the early days of ERP, the gap between how programmers thought the work should get done and how it really got done was significant. Fast forward 10 years and the gap has narrowed, but when you make a living in an industry with highly specialized project management and accounting requirements like building material supply, even a narrow gap can be daunting.

Remember, the main purpose of all ERP solutions is to enable employees to be more efficient. The more an application mimics how employees already work in the real world, the more it will be used, and the more efficient they are. The resources required to train existing employees, force adoption, and reengineer business processes to us a system that is not intuitive may not be justified by the hoped- for long-term gains. The easier an application can integrate into existing operations, and the closer it mimics industry-proven practices, the greater the opportunity to realize a Work Small, Win Big benefit.

Creating Busienss Assets

Tribal Knowledge is a nickname given to crucial yet undocumented information or processes relating to a specific job, task, customer, or project. Tribal knowledge is passed from one employee to the next on an informal basis, or as the need arises, and is not retained by a company once the employee who owns the knowledge leaves.

Tribal knowledge can be:

• Special arrangements made between customers and vendors, such as relationship- based pricing, freight policies, or credit terms;

• Contact information of trusted suppliers that resides only in a personal cell phone or home PC; or

• Complex, Excel-based project management or accounting workarounds constantly reinvented by different employees attempting to solve the same problem.

Tribal knowledge is often crucial, yet never recorded in a way that makes it an asset of the entire company. Converting tribal knowledge into ownable IP, proprietary systems, standard workflows, or efficient processes is a key benefit of a comprehensive ERP solution. Once recorded, it becomes an asset that can be shared to drive revenue, maintain quality, increase margin, or enhances valuation.

Evaluation of ERP

There are four different types of ERP solutions available to the building products supply industry, and like many things, there is no one right solution. What works for your biggest competitor might not work for you, so it’s important to look at your business needs objectively to find an ERP solution that meets the criteria you’ve set out.

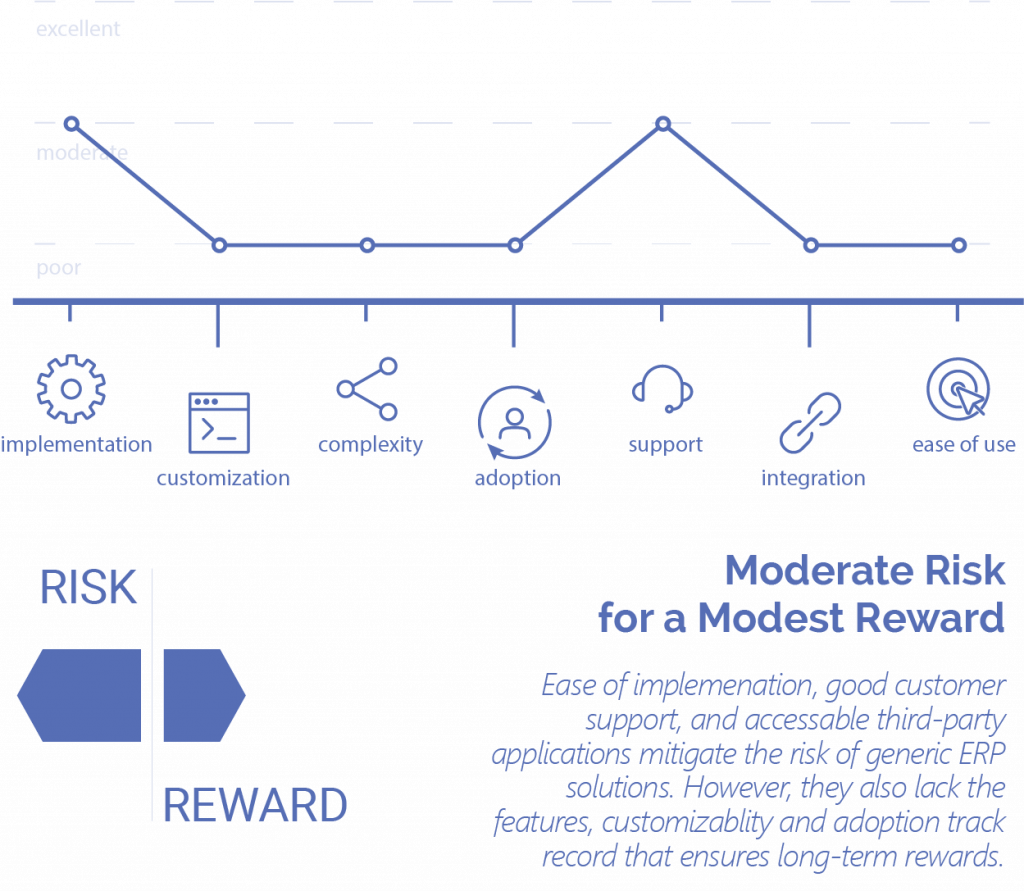

It is best to stick to a defined set of parameters when evaluating different solution types, thereby keeping the comparisons as uniform as possible. There are many issues to consider, but for the sake of this analysis, let us keep to the following basic criteria: implementation, customization, complexity, adoption, support, integration and ease of use.

Generic ERP

We’ll begin with the off-the-shelf variations of ERP software that cover basic business needs like accounting, inventory, sales, and purchasing. Generic ERP software is perhaps the easiest to install, but also difficult to customize or retrofit into unique workflows. To remain attractive to the largest possible market while still providing for individual requirements, generic ERP solutions will usually integrate with popular third partie applications. But even here the emphasis is on simplicity, and robust functionality is abandoned in favor of widely applicable features. So, for example, a window and door manufacturer who wants to integrate estimating and engineering into his automatic processes probably won’t get everything he needs to take control of the future of his business.

Generic ERP systems are not designed with specialized industries in mind, so chances are employees will need to undergo substantial training to efficiently leverage even basic functionality. A clear upside, though, is that a generic feature set and integration landscape are easier and more straightforward to support – as long as you’re not trying to make the software do backflips it wasn’t designed to do. A generic ERP platform will also likely boast a seasoned customer support department and knowledge archive that will prove to be valuable assets for a business that is likely to choose this option in the first place.

A simple, less mature product supply business with a minimal catalog and little special order traffic, especially one that does not plan on growing or changing dramatically in the coming years, would do well to consider a generic ERP solution. It is not realistic to expect a Work Small/Win Big benefit from this kind of solution because the business is relatively simple to begin with and there is not a lot of complexity to mitigate. However, there certainly is an advantage to automating basic business processes and accounting tasks, and the ease of implementation and support will help users get there quickly. All in all, generic ERP solutions represent a moderate risk, and a minimal reward.